Carpet Cleaning Chemistry and Aftercare

Carpet cleaning chemistry breaks the bond between fibers and soils, proteins, oils, tannins, and odor sources, so extraction can remove them without sticky residue. A complete process matches the right pre-spray family (enzymatic, solvent infused, oxygenated) to the soil and fiber, adds targeted agitation and dwell, finishes with a balanced rinse to return pH near neutral, and uses simple aftercare to speed drying and prevent wick-back.

Keeping carpets fresh isn’t only about machine power. Chemistry decides if lanes stay clean for months or gray out within weeks. The right approach starts with soil identification, pairs the chemistry to fiber and risk, uses measured agitation, and insists on a clean finish with no film left behind. Aftercare then locks in the result.

If you want a side-by-side look at service methods and where each fits, see carpet cleaning methods compared for a practical overview that pairs neatly with the chemistry below.

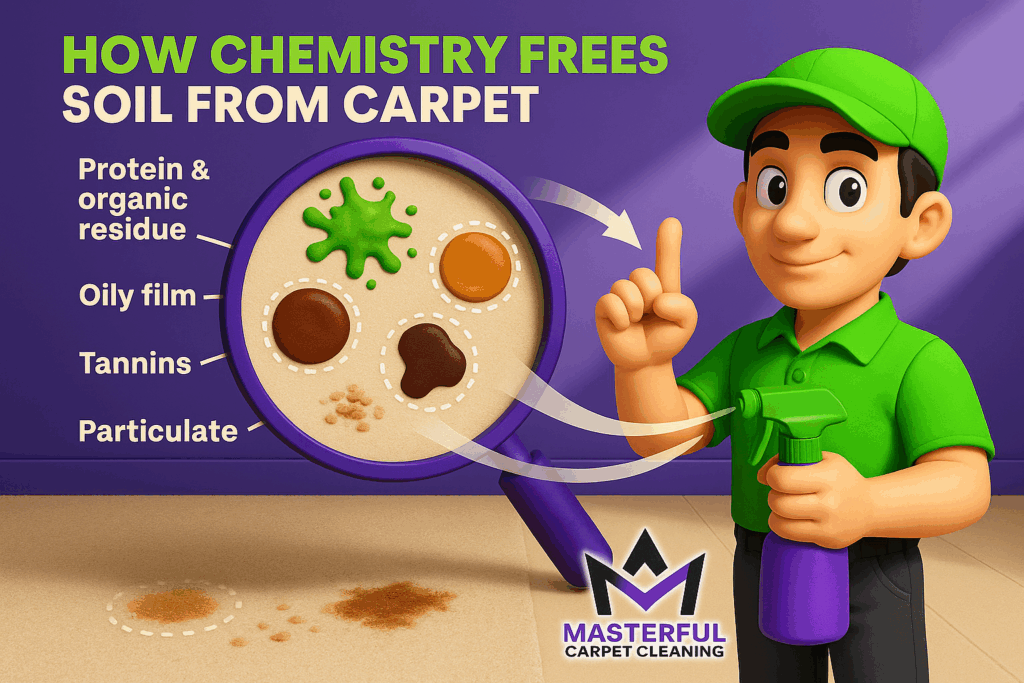

How chemistry frees soil from carpet

Soils stick to yarn in different ways. The aim is to weaken each bond so the rinse can carry the soil away.

- Protein and organic residues (food, dairy, body fluids, pet accidents). Long chains respond to enzymatic action given time and moisture.

- Oily films (body oils, cooking aerosols, cosmetics, asphalt walk-in). Surfactants and mild solvent boosters cut the film that glues dust to yarn.

- Tannins and color bodies (coffee, tea, wine). Controlled oxygen sources can brighten and normalize tone after the main clean.

- Particulate (sand, grit, dust). Dry soil vacuums out, yet oils can lock fines in place. Break the film first, then rinse.

Chemistry isn’t a guess. It’s a match between soil, fiber, and risk tolerance, followed by a rinse that leaves nothing sticky behind.

The four pre-spray families and where they shine

1) Enzymatic pre-sprays (protein heavy problems)

Enzymes break down protein chains into small pieces that lift during extraction. They need even coverage, moisture, and dwell. Warm solution helps; drying does not. Light agitation exposes fresh chemistry to the soil.

Use for: food tracks, dairy drips, many pet spots.

Watch: wool or unstable dyes; keep temps modest, spot test, and rinse thoroughly.

Tech notes

- Uniform application wins. Edge-to-edge coverage beats “hot spots only.”

- Give enzymes the window they need, then remove them. Leaving enzyme residue is never the goal.

2) Solvent infused pre-sprays (oily lanes and film)

This family targets body oils, cooking residues, cosmetics, and asphalt transfer. Modern surfactant systems knock down surface tension while mild solvents loosen stubborn film.

Use for: traffic lanes near kitchens and entries; makeup shadows near vanities; office lanes.

Watch: ventilation. Keep dwell reasonable, rinse to a neutral finish, and avoid any lingering scent.

Tech notes

- Agitate lanes. A counter rotating brush (CRB) or pad driver helps chemistry reach all yarn sides.

- “More” isn’t better. Correct ratio plus agitation beats heavy application.

3) Oxygenated pre-sprays (tannins and tone issues)

Oxygen sources brighten and help with certain color bodies after the main clean. They’re not a silver bullet, yet they can refine the result on coffee, tea, and some wine shadows.

Use for: a finishing pass on stains that stayed slightly tinted after extraction.

Watch: wool and other natural fibers. Keep contact controlled; spot test every time.

Tech notes

- Treat oxygen like seasoning: a measured touch after the heavy lifting, not a blanket approach.

- Always balance with a clean rinse.

4) Neutral/surfactant sets (delicates and unknowns)

When fiber identity is uncertain or the piece is delicate, a mild surfactant set with careful temperature and a balanced rinse is the safer path.

Use for: wool, natural blends, patterned and loop constructions where texture can distort.

Watch: agitation pressure. Let chemistry do the work.

Simple match matrix (read across)

| Soil family | Common situations | Safer fiber targets | Pair with | Watch for |

|---|---|---|---|---|

| Protein/organic | dining areas, playrooms, pet zones | synthetics; test natural fibers | enzyme pre-spray + time + light agitation | dye movement on unstable goods |

| Oily film | kitchens, entries, makeup areas, office lanes | all fibers; gentle approach on delicates | solvent pre-spray + mechanical agitation | rinse thoroughly and ventilate |

| Tannins/color bodies | coffee bar, tea drinkers, wine night | synthetics; cautious on wool | oxygen step after main clean + balanced rinse | overuse on natural fibers |

| Mixed/general | most rooms, routine soil | all fibers | mild surfactant set + balanced rinse | residue that attracts soil |

This matrix guides product choice, tool selection, and dwell. The result is predictable soil release without over wetting or texture distortion.

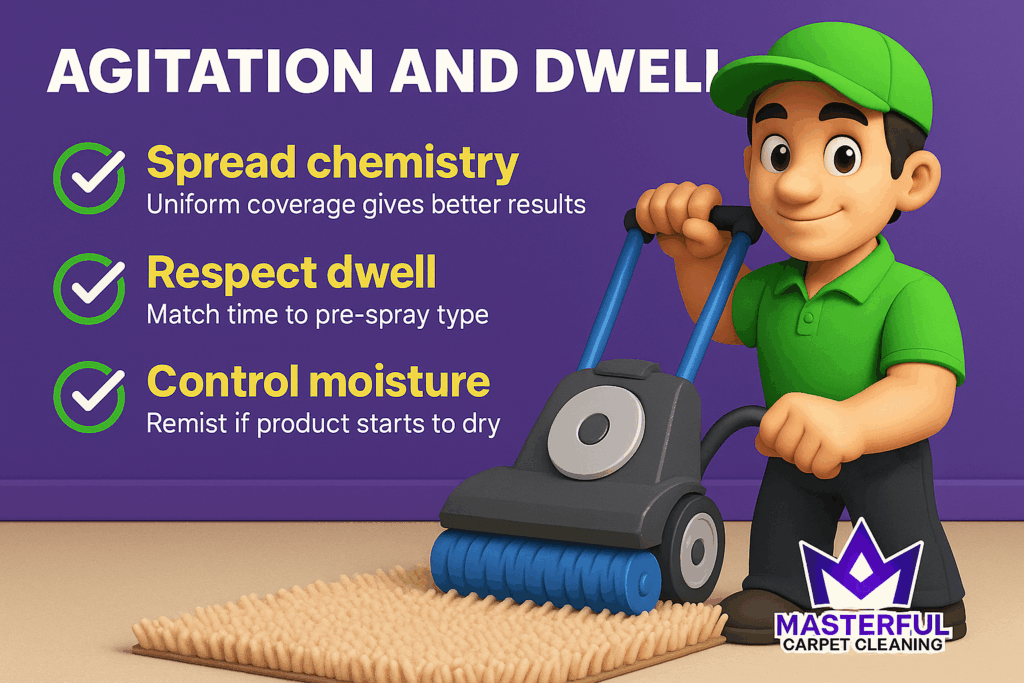

Agitation and dwell: chemistry without harm

Agitation spreads chemistry and exposes new surfaces of soiled yarn. The goal is even coverage and controlled dwell.

Tools that earn their keep

- CRB (counter rotating brush). Lifts pile, picks up lint, and works chemistry through yarn tips.

- Soft brush for delicate constructions.

- Pad driver with an appropriate pad for loop piles and commercial glue-down.

How to keep it safe

- Match brush stiffness to fiber and construction. Loop pile, Berber, and shag call for restraint.

- Respect dwell windows. Enzymes need time; solvent boosted sets do their work quickly.

Moisture control

- If a product starts to dry before extraction, re-mist lightly rather than over applying concentrate.

- Edges and entries deserve special care; soil loads there are higher.

Rinse and neutralization: the finish that keeps lanes cleaner

The rinse is more than water. It’s a controlled flush that returns the carpet close to neutral pH and removes leftover surfactant so no sticky film attracts fresh soil.

Practical steps

- Pressure and flow set for the job. Deeper pile isn’t an invitation to flood; it’s a call for measured passes.

- Slow, even extraction strokes. Give the wand time to carry away what chemistry freed.

- Extra dry passes in lanes and spill zones. Seconds spent here repay you with faster dry times and lower wickback risk.

- Groom the pile. A quick rake stands yarn upright so air reaches more surface area.

A balanced finish gives that soft hand people notice and the longer-lasting clean they hired you for.

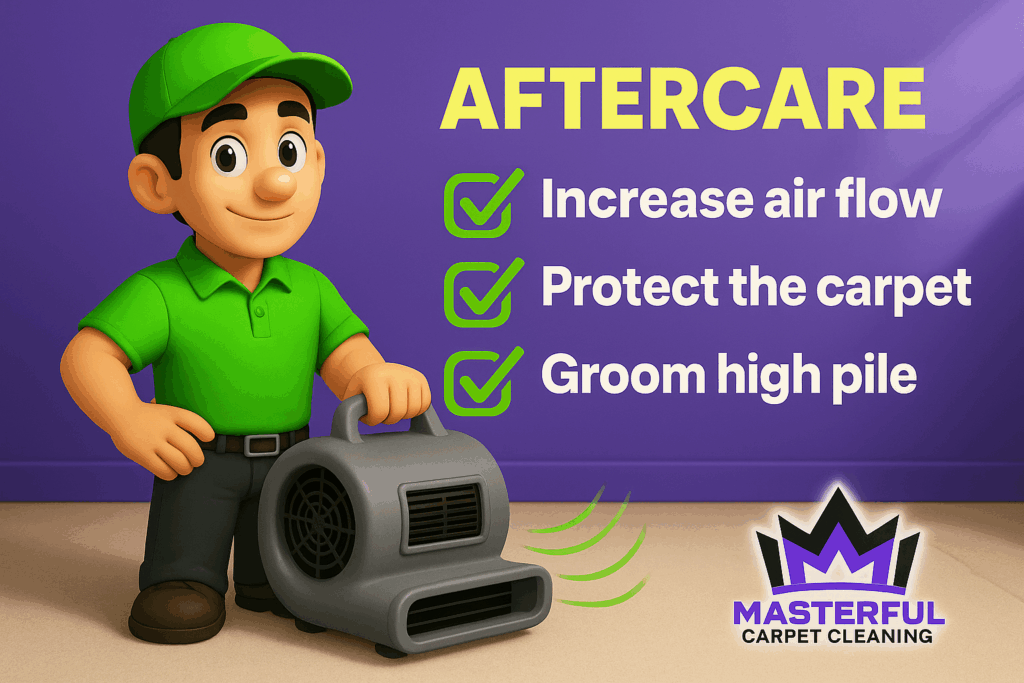

Aftercare that changes outcomes

What happens after the visit makes a big difference. A few small moves keep results stable and speed evaporation.

Airflow and temperature

- Open interior doors and at least one window to create cross breeze if weather allows.

- Run the HVAC fan or portable fans to move air across cleaned areas.

- Keep rooms comfortably warm and low in humidity for the day.

Traffic and furniture

- Step carefully in clean socks once the surface feels dry to the touch.

- Leave protective tabs and blocks in place until everything is fully dry.

- Avoid rolling chairs and carts until tomorrow.

Grooming

- Lightly rake high pile areas so fibers set evenly. This reduces shade lines and helps airflow reach lower portions of the yarn.

Expectations

- Dry times vary by pile, humidity, chemistry choice, and how thorough the extraction was. Many homes finish drying the same day; thicker or denser carpets may need overnight.

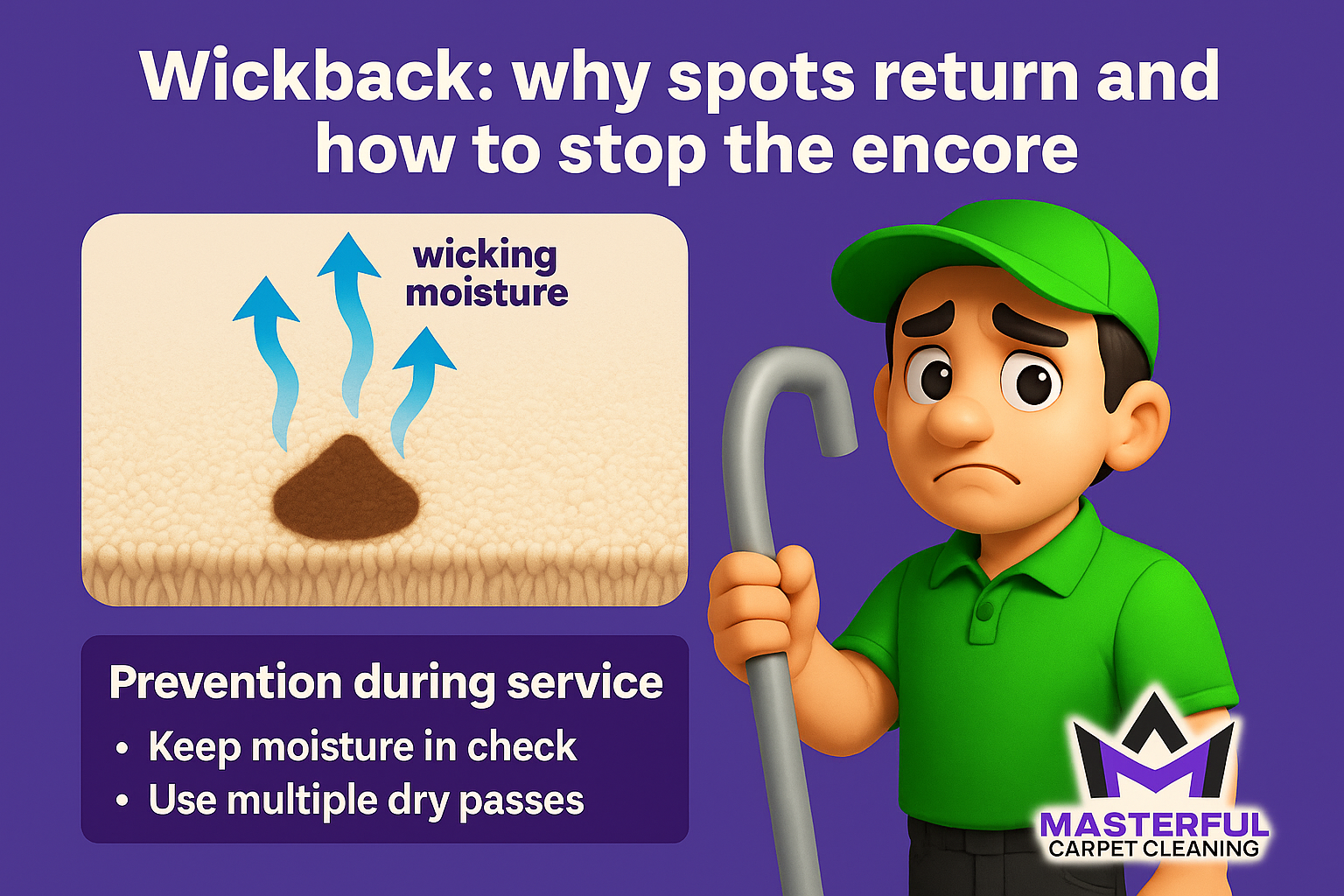

Wickback: why spots return and how to stop the encore

Wickback is the reappearance of a spot as moisture from the backing or cushion rises during drying and brings discoloration with it. Flooded spills, sugary drinks, and residues buried below the face yarn are common triggers.

Prevention during service

- Keep moisture in check, especially over subfloor seams and cushion edges.

- Use multiple dry passes in spill zones and traffic lanes.

- Place absorbent pads over heavy spills after the rinse to draw up subsurface moisture.

If a spot shadows back at home

- Boost airflow and blot gently with a clean towel.

- Avoid spotters that leave soap behind.

- If the shadow holds, schedule a targeted flush and post treatment. Most reappearing spots respond once the subsurface is addressed.

Protector and deodorization: when to say yes

Protector after cleaning creates a low energy surface that buys extra time during spills and makes vacuuming more effective. It’s a smart add-on for family rooms, stairs, hallways, and offices with rolling traffic.

Application basics

- Apply evenly while the carpet is clean and slightly damp.

- Groom for full fiber coverage.

- Let the area dry without foot traffic for the recommended window.

Deodorization paths

- Enzyme treatment addresses odor at the source where organic residues remain.

- Oxidation targets odor bodies that enzymes don’t neutralize. Severe pet issues sometimes need both stages, plus subsurface treatment if the cushion or subfloor holds contaminants.

Fiber specific notes that prevent headaches

Different fibers respond in different ways to chemistry, heat, and agitation. Respect those differences and the job goes smoothly.

Nylon

Durable and forgiving. Accepts a wide range of pre-sprays when rinsed to neutral. Great candidate for solvent infused chemistry in busy lanes. Watch for fiber wear in older traffic paths; cleaning won’t “fix” crushed texture, yet it will remove the film that highlights it.

Polyester/Triexta

Resistant to many dyes yet attracted to oils. Lanes near kitchens and play areas often benefit from a measured solvent boost plus mechanical agitation. Rinse well to a clean finish, then groom.

Olefin/Polypropylene

Resists many water based stains yet attracts oily soils. Wicking can be common in commercial glue down and in basements. Control moisture and invest in thorough extraction.

Wool

Beautiful hand and long life when handled carefully. Choose mild chemistry, modest temperatures, and gentle agitation. Extra dry passes help keep the finish soft. For a richer look at handling, see wool carpet maintenance.

Patterned and loop constructions

Respect the texture. Keep agitation light, avoid snagging, and watch tool selection around seams and transitions.

Safe spot sequences for common issues

Food spill (protein heavy)

- Lift or blot loose material without grinding it in.

- Apply an enzyme pre-spray; keep it moist for the dwell window.

- Light agitation with a soft brush.

- Balanced rinse with slow strokes and extra dry passes.

- Groom and ventilate.

Traffic lane film

- Vacuum with care to pull dry soil from down in the pile.

- Apply a solvent infused pre-spray on lanes; use a standard set nearby to blend.

- Agitate lanes with CRB or a suitable pad.

- Balanced rinse; several dry passes through the worst areas.

- Groom and increase airflow.

Coffee or tea

- Spot test for dye stability.

- If dairy is present, give an enzyme step first; rinse.

- Apply a measured oxygen step; rinse again and groom.

- Improvw airflow and keep traffic off until dry.

Makeup or cosmetic transfer

- Limit spread by blotting gently.

- Solvent infused pre-spray in small, controlled passes.

- Rinse thoroughly and perform extra dry passes.

Pet accident (fresh)

- Extract gently to remove free liquid without pushing it wider.

- Enzyme pre-spray; allow dwell with light coverage to keep it moist.

- Rinse to neutral and perform extended dry passes.

- If odor lingers, apply a finishing oxygen step and ventilate.

Myths that waste time (and money)

- “Hotter is always better.” Heat helps, yet fiber type and dye stability set limits. Wool and some patterned goods prefer modest temperatures.

- “More soap means a cleaner carpet.” Extra surfactant without a proper rinse leaves a sticky film that grabs soil.

- “One method covers every job.” Homes, fibers, and soils vary. Pick the process to match the material and problem. If you want a clean comparison to share with clients, point them to carpet cleaning methods compared.

- “If a spot returns, the tech missed it.” Wickback often comes from subsurface moisture and buried residue, not from effort. A targeted flush usually solves it.

FAQs

What does a balanced rinse do? It returns the carpet to a neutral state while flushing away loosened soil and surfactant. The finish feels soft and lanes stay clean longer.

Why do some carpets resoil quickly after DIY cleaning? Leftover soap forms a film that grabs dust and oils. A balanced rinse with extra dry passes removes that film.

How long before walking on the carpet? Walk in clean socks once the surface feels dry to the touch. Save regular shoes and rolling chairs for later in the day, or the next day, based on humidity and pile depth.

Are enzymes safe for wool? Use mild chemistry, cooler solution, and careful dwell. Always spot test and finish with a balanced rinse.

Does protector really help? Yes on busy paths, stairs, and rooms with kids or pets. It buys time during spills and makes vacuuming more effective.

What’s the best method for my home? The right choice depends on fiber, soil load, and access. If you want to compare processes with pros and cons, read carpet cleaning methods compared.

How technicians decide during a visit (process overview)

- Inspect and identify. Fiber, construction, dye stability, seam layout, and soil types set the plan.

- Pre-vacuum. Removing dry soil keeps chemistry focused on what truly needs it.

- Choose chemistry and apply evenly. Match pre-spray family to soil and fiber.

- Agitate and manage dwell. CRB or brushing for coverage; keep the product from drying.

- Rinse to a neutral finish. Slow strokes, measured pressure, correct flow.

- Dry passes and grooming. Extra extraction in lanes and spill zones; rake to stand yarn up.

- Aftercare briefing. Airflow, traffic guidance, and furniture tab timing.

This sequence isn’t flashy, and that’s exactly why it works: each step supports the next without leaving behind residue or moisture that causes callbacks.

Where to go next

Curious how equipment and chemistry line up for different scenarios? Compare options on carpet cleaning methods compared and match them to your rooms and fibers. Caring for natural pile? Keep wool carpet maintenance handy for safe handling notes that complement the chemistry on this page.

As the Co-Owner of Masterful, Randy has been providing quality cleaning services to the Salem and Portland areas of Oregon for many years. He has built a reputation for excellence in the industry. His team take prides in using the latest cleaning techniques and technologies to deliver exceptional results every time. Author